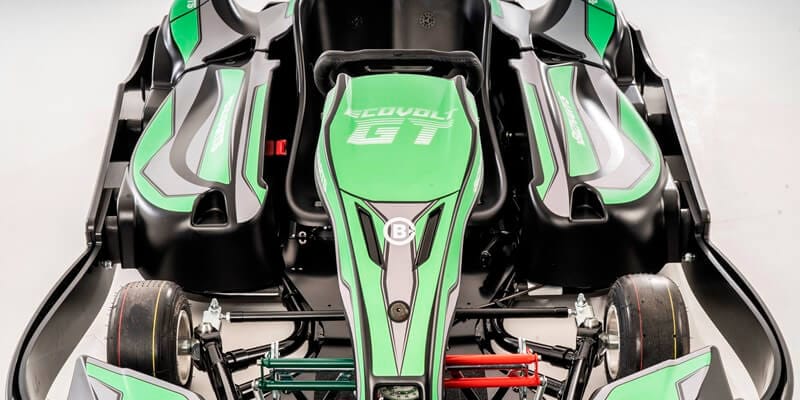

Go-karting legends Bizkarts recently contacted us to request a quick turnaround of some new bodywork prototypes and we were more than happy to help.

The new EcoVolt GT kart was in development and with potential customers keen to see how the new kart would look it made sense to use our 3d printing service to quickly produce prototype bodywork. The prints were completed with low cost PLA to provide cost effective form and fit models to mount onto the new kart chassis.

Whilst the pieces could have been completed in one piece using our new Modix 120x large format machine, the amount of support material would have been excessive and the parts overly expensive. In this case it made sense to balance the cost with the requirements for the final print and since the objective was to show the general form and test fitment we agreed to split the model and print in multiple pieces. Splitting the model reduced the need for support material and subsequently reduced cost significantly. We finished the prints by assembling the pieces and delivered the parts in person!