Design for Additive Manufacturing: A Case Study

Every manufacturing technology has its strengths and limitations. All professional designers and engineers understand this and optimize their designs accordingly. It also means that, in some cases, you can make a significant impact on the end part or product simply by shifting processes and optimizing your design accordingly.

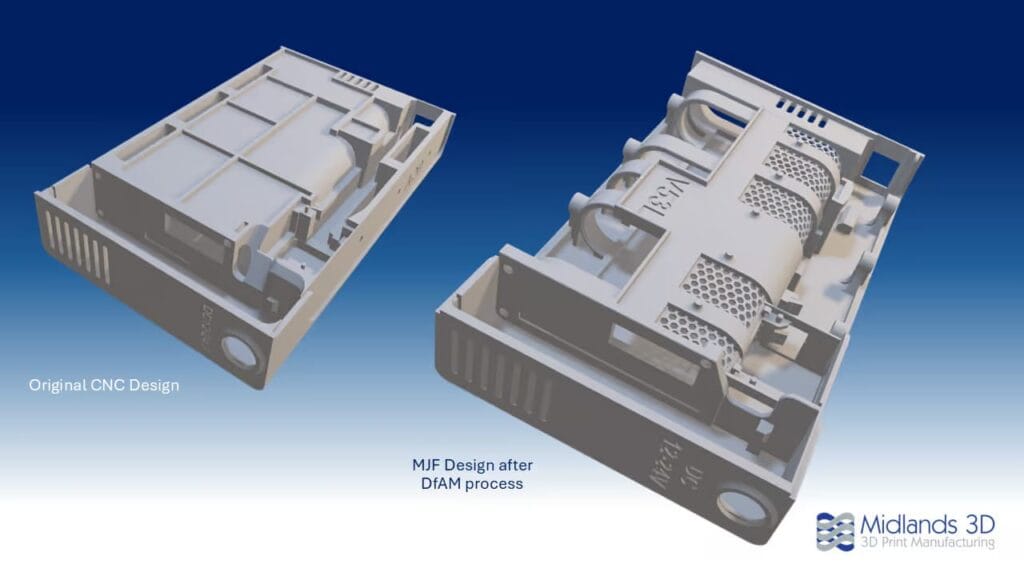

In our world, this process is called Design for Additive Manufacturing (DfAM). In this case study, we explain how that process was able to shave one-third of the weight out of a part simply by optimizing it for MJF (Multi Jet Fusion) printing.

Overall Weight: A Major Challenge

The part in question was part of a system of electronics designed to be carried in a backpack. Four were needed in each system, each holding one of the required batteries. Overall weight in the system was a key factor, and so opportunities for weight reduction were being sought across the entire design.

The Limitations of the CNC-Based Design

The part we were asked to review using DfAM techniques had originally been designed for CNC machining – a subtractive process that imposes inherent design limitations due to the need to machine parts from a solid block of material.

As a result, the design included numerous areas of unnecessary material, left in place purely to facilitate manufacturability.

Transitioning to Multi Jet Fusion (MJF) Technology

The shift to additive manufacturing using Multi Jet Fusion (MJF) liberated the design process from these traditional constraints. The MJF process opens up virtually limitless possibilities in geometry, allowing us to focus solely on the functional requirements of the part.

MJF Frees Up Design and Manufacture

- Negligible Manufacturing Constraints: Freedom to produce any geometry.

- Enhanced Functional Design: Ability to focus on essential features without compromise, and to add additional features into the design that might otherwise have had to be added during assembly.

- Ease of Iteration: Modify your design on every print – or send different versions to be printed together, all with no additional manufacturing cost.

- Production and Customisation at Scale: The MJF process is suitable for end use parts whether you need one, or hundreds at a time – all on short lead times with minimal set up. Need each to be slightly different? Also easily done.

Enhancements to Further Improve the Solution

Alongside the striking weight reduction, our design in this case also included practical enhancements such as the addition of brass threaded inserts – another in-house service that we provide. These additions safeguard thread longevity, ensuring a robust and durable finish that’s as lightweight as it is functional so the product can be disassembled and reassembled many times with no loss of functionality or accuracy.

Midlands 3D’s DfAM Expertise

At Midlands 3D, we provide expert advice to organisations looking to either create new designs or modify existing ones to make the switch to additive manufacturing. Our in-house design team can also help you unlock the potential of 3D printing as well as guide you to the right technology choice, whether FDM, MJF, SLA or even now SLS TPU printing – all delivered in-house on machines we operate.

We’ll work with you to refine and enhance component specifications, pointing out additional capabilities that can be incorporated at no cost – such as the cable clips and guides that were designed in on this project.

The Takeaway

Innovation is within reach for anyone willing to embrace emerging technologies like MJF. If your components echo the bulky models of the past, consider venturing into the future. DfAM opens pathways to cutting-edge solutions that are lighter and more efficient, and production methodologies that are far more agile.