Smarter design. Faster production. Precision parts for machine building and automation.

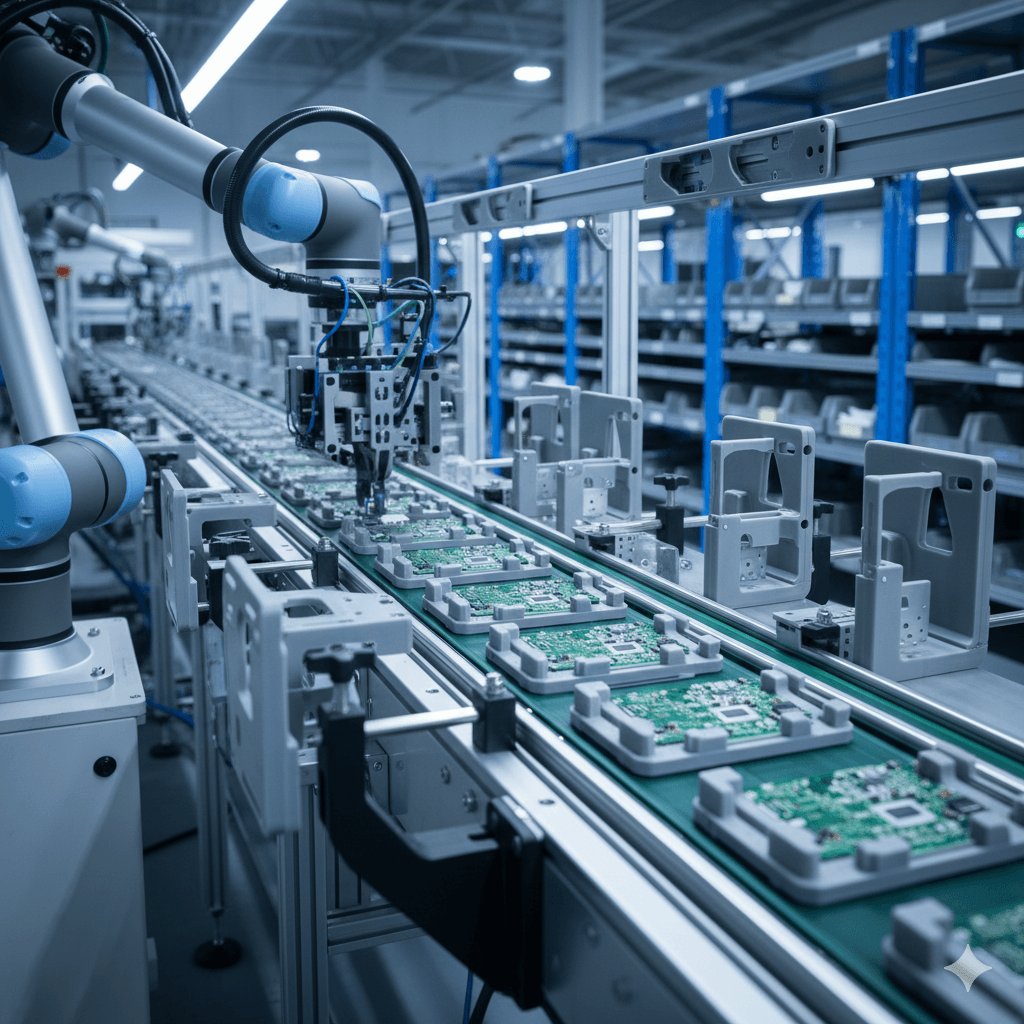

3D printing brings agility and innovation to manufacturing and robotics, delivering custom solutions that enhance productivity and reduce costs. Midlands 3D provides on-demand parts for key applications including:

- End of ARM Tooling (EOAT): Grippers tailored to your automation setup for precise handling and movement

- Jigs & Formers: Bespoke tools for assembly, QA, and production that are fast to produce and easy to replicate

- Fixtures and Guides: Lightweight, durable supports and guides designed for your workflow

- Custom Fittings: One-off connectors and adaptors to improve system performance and flexibility

Whether you’re streamlining manual processes or upgrading automated lines, 3D printed parts offer fast turnaround, reduced tooling costs, and seamless integration into existing operations.

Why Choose Midlands 3D in Manufacturing and Robotics

Digital Warehousing & On-Demand Spares

Stop stocking shelves with spares, jigs, or moulds and store them as digital files instead.

Midlands 3D helps manufacturers digitise tooling and component inventories, enabling secure online storage and on-demand 3D printing. When a part is needed, it’s reproduced quickly and accurately, reducing lead times and downtime.

- Cut inventory costs by eliminating low-use physical stock

- Free up warehouse space with digital storage

- Minimise production delays with rapid part reproduction

- Preserve legacy tooling via 3D scanning of formers, grippers, moulds, etc.

Digital warehousing transforms spare part management into a lean, cost-effective process—ideal for modern manufacturing environments.

Parts for Machine Building

Machine builders rely on robust, reliable, and customizable components. At Midlands 3D, we provide on-demand 3D-printed parts that form the building blocks of bespoke machines, automated systems, and robotics.

From structural brackets and custom housings to lightweight grippers and guides, our parts are designed and optimised for strength, precision, and efficiency. Work with Midlands 3D to produce:

Custom Brackets & Mounts for Machine Assemblies

Protective Housings & Enclosures for Sensors and Actuators

Lightweight, Complex Parts for Robotics and Automation Systems

Materials and Technologies that are up to the job.

With a wide variety of polymer based materials to choose from and MJF, FDM, SLS and SLA technologies all operated in-house, we can guide you to the optimal combination of material and process to meet the task at hand and the budget available.

For example, you might need the soft touch and flexible properties of TPU for end of arm tooling and work holding applications, or ESD protection where static build up needs to be minimised for handling electronic assembly. You might want the strength, resilience and precision of a MJF printed PA12 Nylon part, or the quick and cost-effective turnaround of FDM prints in PETG or PLA.

Talk to us and we’ll help you come up with the right combination for your use case.

Experts in 3D Printing for Manufacturing and Robotics

Our in-house facility produces production-grade 3D prints for robotics, industrial manufacturing, and other advanced applications. Your intellectual property remains secure, lead times are reduced, and your projects receive genuine consultative support—not generic service.

Whether adapting manufacturing lines or robotic systems for new applications, replacing aging components, or exploring more efficient tooling solutions, we’re accessible and ready to help you implement professional, high-quality 3D printing at scale.

We understand confidentiality is essential and take your trust seriously. That’s why we routinely work under strict Non Disclosure Agreements, whether initiated by you or us. These agreements are fundamental to protecting sensitive information. We also produce all jobs in-house, minimising IP infringement risk and ensuring quality.

We’re proud to hold certifications in Cyber Essentials and ISO 9001, reinforcing our commitment to secure, quality-focused processes.

FREE Sample Print for Qualified Enquiries

If you need a fast, reliable, and experienced partner to help drive efficiencies and increase agility on your production lines, Midlands 3D is here to help.

Let us show you what we can do — get in touch and we’ll 3D print a sample part from your design, or we can send you a sample from designs we own.

Talk to Us. Visit Us.

Talk to us and find out what makes working with Midlands 3D so different. If you’ll be in the area, why not arrange to stop by for a guided tour of our manufacturing facility, meet the team and browse our showroom for inspiration.