Additive Manufacturing for Production Parts, Tooling, and Specialist Applications

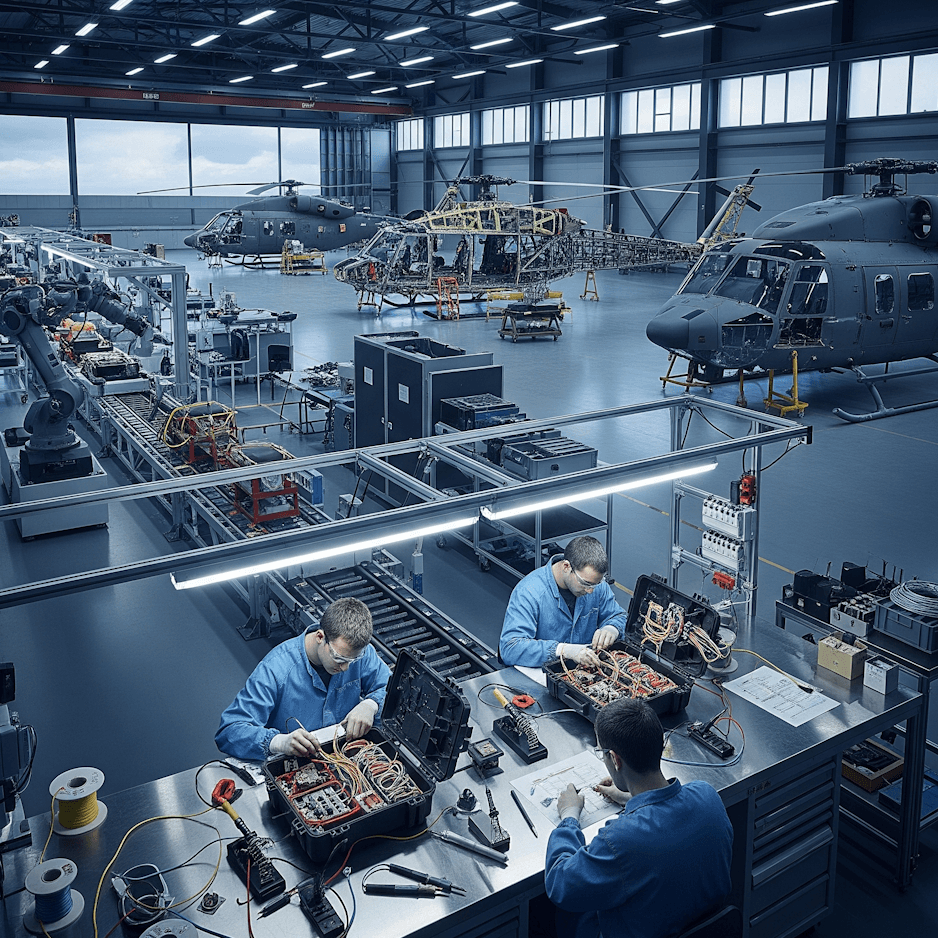

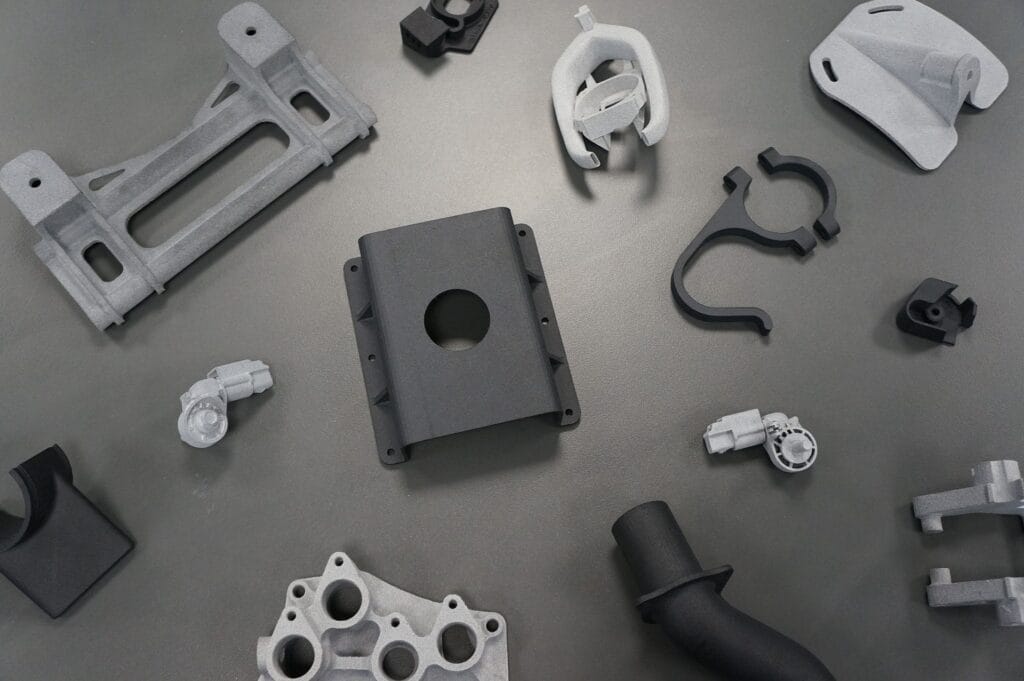

The UK Defence sector is undergoing a step-change in capability and resilience, driven by the MOD’s Defence and Security Industrial Strategy (DSIS) and the adoption of advanced manufacturing under Project TAMPA. Additive Manufacturing (AM) is at the heart of this transformation, enabling suppliers to deliver lightweight, durable, and rapidly deployable solutions across the Defence supply chain. Midlands 3D is a trusted partner to the UK Defence sector through SMEs, and tiered suppliers, providing on-demand 3D printing of both production parts and tooling, jigs, formers, moulds and similar in the supply chain.

As a JOSCAR-registered, Cyber Essentials accredited, and Make UK Defence member, we bring proven capability, compliance, confidentiality and security to every Defence project we undertake.

Why Choose Midlands 3D for Additive Manufacturing in the Defence Supply Chain?

Supporting MOD Project TAMPA and the Defence Advanced Manufacturing Strategy

Project TAMPA is the UK MOD’s initiative to embed additive manufacturing within the Defence supply chain, ensuring operational advantage, sovereign capability, and supply chain resilience.

By aligning with this strategy, Midlands 3D helps suppliers:

- Accelerate time to capability through rapid prototyping and batch production.

- Reduce dependence on complex global supply chains with local, agile AM solutions.

- Enhance operational readiness with deployable spares and lightweight parts.

- Support sovereign capability in line with DSIS priorities.

Our additive manufacturing expertise directly supports the MOD’s focus on resilience, agility, and innovation across land, sea, air, and space domains.

Defence Applications for Additive Manufacturing

Midlands 3D’s experience spans across multiple applications in the Defence sector:

- Unmanned and Autonomous Vehicles (UAVs, UGVs, USVs, UAS): Lightweight and structurally optimised printed components for drones and unmanned systems.

- Production Parts: Low-volume, bespoke, and high-performance parts for Defence-grade applications.

- Tooling & Jigs: Precision formers, fixtures, and jigs to support the manufacturing of a range of systems.

- Composite Tooling & Moulds: Additively manufactured patterns and moulds for aerospace and Defence composites.

- Rapid Sustainment & Spares: On-demand production of replacement parts to maintain fleet readiness.

Partner with Midlands 3D

The Defence sector is embracing additive manufacturing as a strategic enabler of capability and resilience. Midlands 3D is positioned to help suppliers align with MOD initiatives, reduce risk, and deliver innovation at pace.

Sample parts available for qualified enquiries – let us prove the performance.

Contact us today to explore how Midlands 3D can strengthen your Defence supply chain with additive manufacturing.

Talk to Us. Visit Us.

Talk to us and find out what makes working with Midlands 3D so different. If you’ll be in the area, why not arrange to stop by for a guided tour of our manufacturing facility, meet the team and browse our showroom for inspiration.