A Professional 3D Printing Service

3D Printing technologies have evolved rapidly over the last decade or so, making it a very viable choice and with a host of unique benefits when compared to other prototyping and batch manufacturing technologies.

With a range of leading polymer-based technologies in-house, we continually invest in leading edge technology, enabling you to fully capitalise on 3D Printing from prototype, through into production and on into obsolescence planning.

MJF (Multi Jet Fusion)

Designed from the ground up by HP for high volume parts manufacture, Midlands 3D are one of the top 3D Printing Service providers offering this technology in the UK.

A powder-based process, selecting MJF eliminates the “layers” common in other additive technologies and enables you to go from prototype to high quality volume production, all within the same process.

Selecting MJF delivers both speed and efficiency for industrial scale additive manufacturing.

Ideal for:

in an identical process to finished parts

high quality finishes and performance

high quality print manufacturing

Tolerance and Design

- Layer Height – 0.08mm (80microns)

- Tolerance – ±0.3% (min: ±0.15mm)

- Minimum Wall Thickness – 1mm

View our Design Guidelines to learn more about designing for MJF 3D Printing

Build Volume

- 380mm x 284mm x 380mm

When printed, parts are suspended within a build volume, held in a block of PA12 Nylon powder at the optimum print orientation for print quality. Larger parts can be printed in sections and assembled prior to post-processing.

Finishing

- Natural Grey

- DeepDye Black and PolyShot Surfacing

- Vapour Smoothed

Standard MJF Printed parts are a mottled grey finish with an ‘extra strong mint’ texture. Our Print to Product workflow from DyeMansion provides options of PolyShot Surfacing and DeepDye colouring to provide a professional end-use part finish.

Lead Times

- Standard – 5-7 working days

- Express – 2-4 working days

Manufacturing Partner Agreement – Manufacture and delivery to an agreed schedule offering you the best pricing whilst maximising print efficiency.

Material

PA12 Nylon is a strong, durable and versatile material. Known for its excellent mechanical properties, chemical resistance, and low moisture absorption, it is ideal for functional prototypes, end-use parts, and components requiring high strength, and impact resistance.

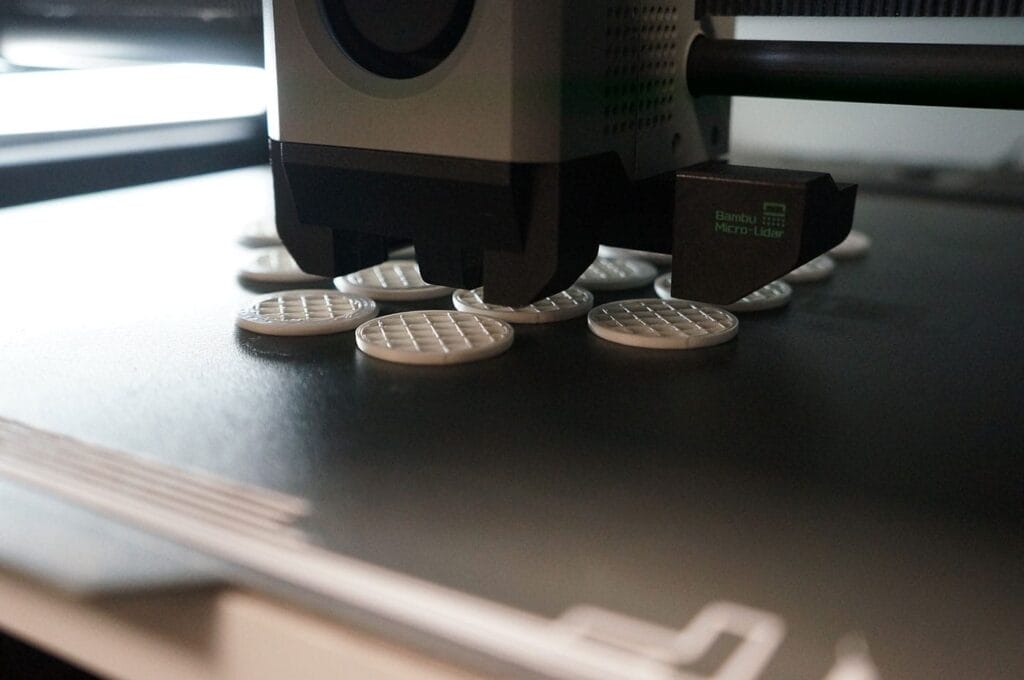

FDM (Fused Deposition Modelling)

Fused Deposition Modelling (FDM), the oldest and most common additive manufacturing process is a great choice for low-cost prints for everything from ‘cosmetic only’ to ‘function over form’ style prints such as internal components, jigs and fixtures. Our fleet of FDM machines provide a 3D Printing service for volume manufacturing and one-off prints where the budget constraints or specific material property requirements make it the best choice. We also offer a multi-colour FDM 3D printing service. This allows us to produce objects with complex patterns and intricate colour combinations. The result is stunning and highly customisable from one part to the next. Whether you want a full multi colour statue, or a small logo adding to your design, multi-colour FDM printing is the solution.

Ideal for:

functional, cost-effective parts

to quickly visualise, ideate and iterate designs

to cost-effectively test your ideas

Tolerance and Design

- Layer Heights – Draft 0.3mm, Standard 0.2mm, Fine 0.1mm

- Tolerance – ±0.5% (min: ±0.5mm)

- Wall Thickness – By default we use 3 outer walls with a 0.4 nozzle meaning walls are 1.2mm thick as a minimum. With larger nozzle sizes we will reduce the wall count e.g. 0.6 nozzle would be 2 walls giving a 1.2mm wall thickness.

- Infill – Standard infill is 20%, this can change depending on part application and strength requirements.

View our Design Guidelines to learn more about designing for FDM 3D Printing

Build Volume

Our fleet of FDM printers enable the production of one or many orders at the same time.

- Sizes (x,y,z)

- Batch Production – Up to 320mm x 320mm x 320mm

- Large Format (Tall) – 600mm x 600mm x 1200mm

- Large Format (Cube) – 1000mm x 1000mm x 1000mm

- Large Format (Long) – 1200 x 600mm x 600mm

Finishing

FDM prints are easily recognised by their visible layer lines and a generally rough surface texture, results of the layer-by-layer extrusion process. These prints can be filled, sanded and painted for a smoother surface finish if required.

Lead Times

FDM lead time is determined by the complexity, size, resolution and print time of the part(s) requested.

Manufacturing Partner – We will manufacture and deliver to an agreed schedule offering you the best pricing whilst maximising print efficiency.

Materials

FDM printing offers the widest range of materials from recycled and decorative to engineering grade carbon filled nylon. Check our materials page for a full list of available FDM materials. If a custom material is required, we can usually source specific materials if needed.

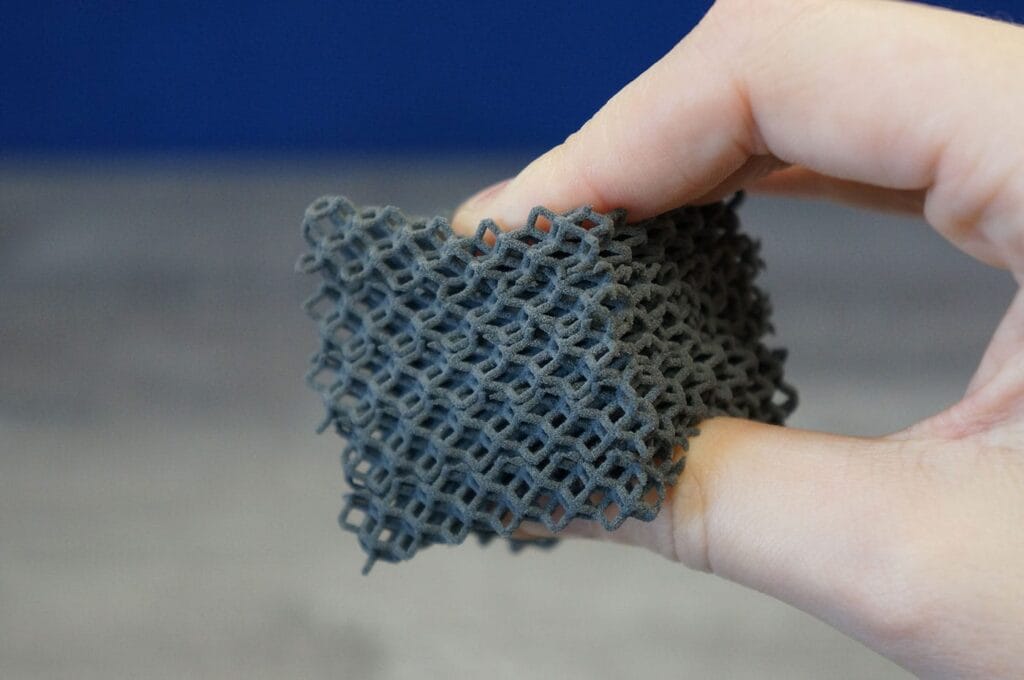

SLS Flexible TPU (Selective Laser Sintering)

If you’re looking for flexible prints with all the benefits of powder-based printing, our SLS TPU 3D printing service is ideal for both one off and batch manufacture.

The flexible TPU 90A material combined with the SLS printing process is a great choice to create complex, resilient and skin-safe parts with the freedom of design offered by the powder-based printing process. Unlike FDM based TPU printing, SLS doesn’t require support material meaning all surfaces have a consistent surface finish regardless of orientation.

Combining the capabilities of the SLS printing process and TPU 90A enables innovative designs such as varying flexibility in a single part, varying part thickness and even adding lattice style structures to give complete design freedom.

Ideal for:

Gaskets, seals, masks, belts, tubing

handles, buttons, straps, wearables

orthotics and other medical aids

dampers, cushioning

Tolerance and Design

- Layer Height – 0.11mm (110 microns)

- Tolerance – ±0.3% (min: ±0.3mm)

- Minimum Wall Thickness – 1mm

View our Design Guidelines to learn more about designing for SLS TPU 3D Printing

Build Volume

- 152mm x 152mm x 294mm

Similar to MJF, SLS suspends parts within the build volume, held in a block of TPU 90A at the optimum print orientation for print quality.

Finishing

- Natural Grey

- DeepDye Black

Standard SLS TPU 90A printed parts are a dark grey with a slightly grainy texture. Add our part finishing to add DeepDye colouring to a rich deep black.

Lead Times

- Standard – 5-7 working days

- Express – 2-4 working days

Manufacturing Partner – We will manufacture and deliver to an agreed schedule offering you the best pricing whilst maximising print efficiency.

Material

TPU 90A is a flexible durable thermoplastic. With a shore hardness of 90A, it offers excellent elasticity, abrasion resistance, and impact toughness, making it ideal for creating functional parts that require flexibility and durability.

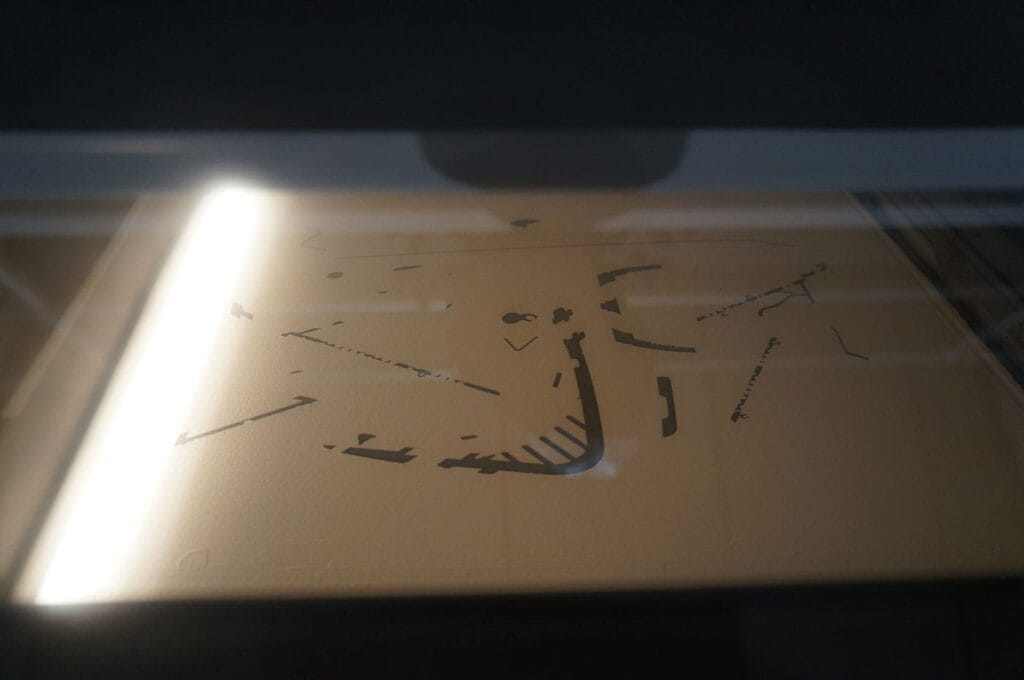

SLA (Stereolithography / Resin)

Stereolithography, also known as SLA or Resin based printing, uses a photopolymer that solidifies when exposed to ultraviolet light. In this process, a laser beam traces the cross-section of a 3D model onto the resin, causing it to harden. Layer by layer, the model is built up until it’s complete.

SLA Resin offers several qualities that make it a preferred choice in specific applications. Specifically, it produces highly detailed and accurate parts with smooth surfaces and fine features. This makes it ideal for prototyping small, complex and intricate designs, yet delivers strength and durability in the finished part.

Ideal for:

Delivering sharp details and smooth surfaces that need minimal post-processing

Great for testing detailed parts where tolerances matter

High-detail masters for silicone moulding or injection moulding

fine aesthetics and customisable design for items like eyewear, phone cases, gadgets and accessories

Tolerance and Design

- Layer Height – 0.05mm (50 microns)

- Tolerance – ±0.15% (min: ±0.01mm)

- Minimum Wall Thickness – 1mm

View our Design Guidelines to learn more about designing for SLA TPU 3D Printing

Build Volume

- 140mm x 140mm x 190mm

Finishing

- Standard Grey

The SLA resin finish is a standard grey colour with smooth surfaces and fine details.

Lead Times

Similar to FDM, lead time for Resin is determined by the complexity, size, and print time of the part(s) requested.

Manufacturing Partner – We will manufacture and deliver to an agreed schedule offering you the best pricing whilst maximising print efficiency.

Material

Standard Resin is known for its smooth surface finish and fine detail capabilities. It offers good strength and rigidity, making it ideal for creating detailed prototyped, models, and parts that require high accuracy and a professional appearance.

Talk to Us. Visit Us.

Talk to us and find out what makes working with Midlands 3D so different. If you’ll be in the area, why not arrange to stop by for a guided tour of our manufacturing facility, meet the team and browse our showroom for inspiration.