Driving Transport with 3D Print Manufacturing

From concept design to track-tested performance and production-ready parts, Midlands 3D is helping automotive designers, engineers and manufacturers reimagine what’s possible with 3D printing. Whether you’re a specialist vehicle builder, motorsport team, or a global OEM, our advanced additive manufacturing capabilities are already being used by businesses like yours to develop faster, create competitive advantage, streamline and de-risk supply chains.

Why Choose Midlands 3D for Automotive and Transport?

Why 3D Print Manufacturing Makes Sense in the Transport Sector

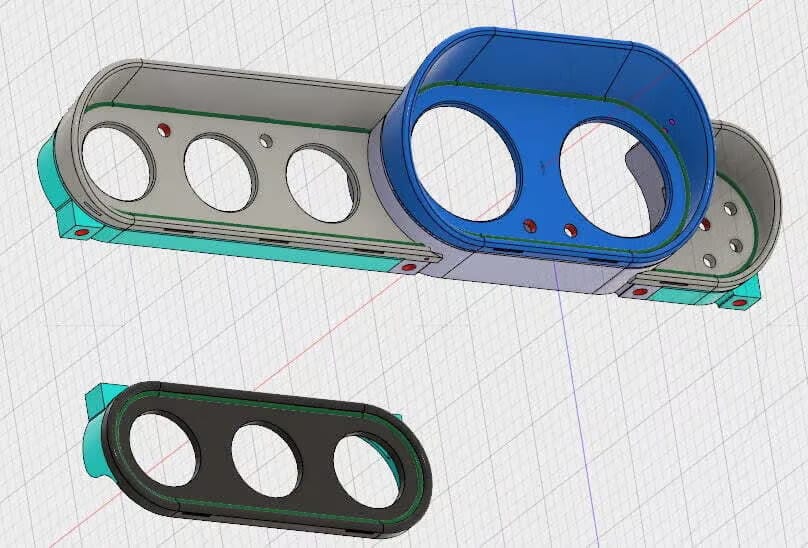

Additive Manufacturing is transforming automotive manufacturing by reducing the cost, time and complexity of traditional processes whilst delivering speed and personalisation into the product development. Midlands 3D supports all stages of the development cycle from one-off prototypes to repeatable end-use parts with a reliable, scalable and cost-effective service.

With the ability to scale from one-off custom applications to batches of hundreds of parts with no set up costs and rapid turnaround times, 3D printing is making the previously unprofitable, achievable.

For Specialist and Low-Volume Manufacturers

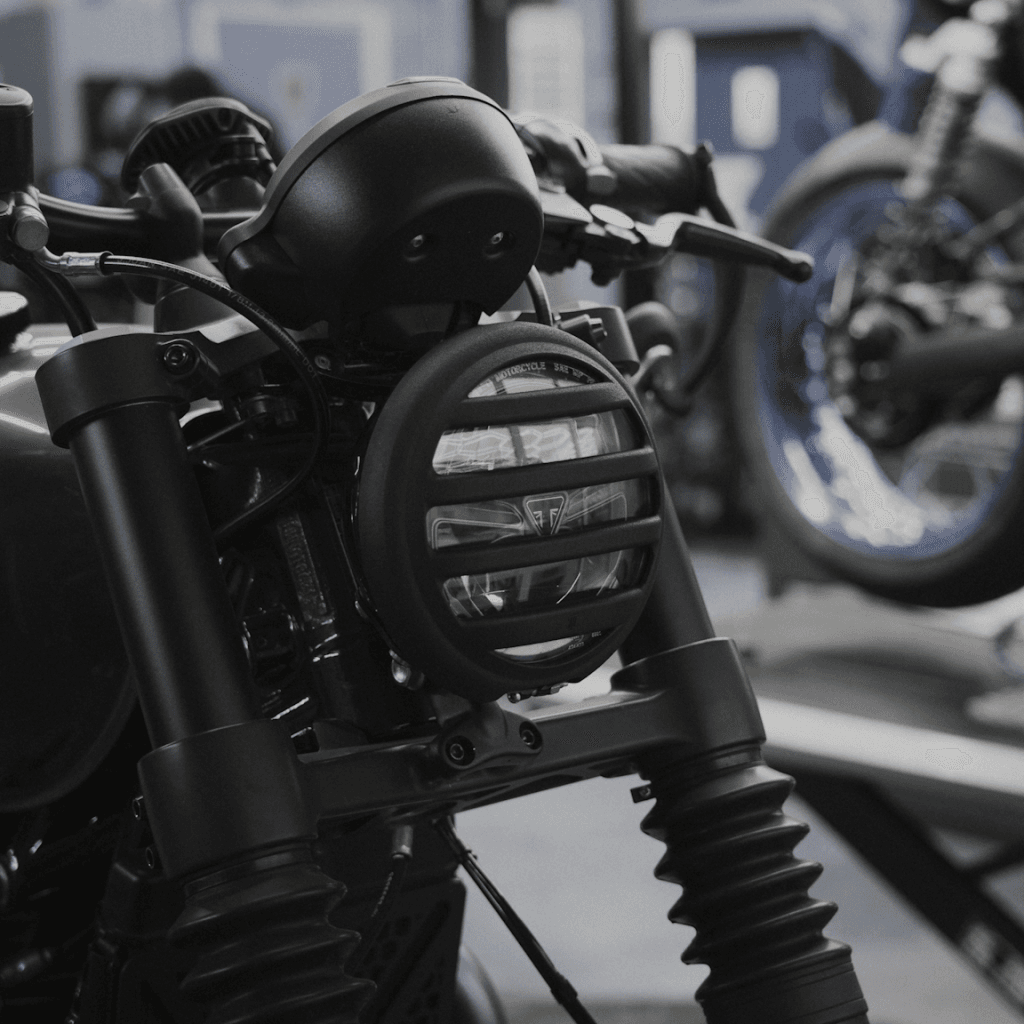

Small and specialist manufacturers benefit from the ability to print parts in low volumes without tooling, ideal for:

- Custom ducts, mounts, housings, and interior features

- Heritage vehicle restoration and one-off builds

- Agile response to design changes or part shortages

- Adaptation for specialist applications, whether at scale for use cases such defence or the Emergency services, or for one-offs to accommodate, for example, specific disabilities.

For OEMs and Tier Suppliers to Global Brands

We regularly work with large automotive brands who are increasingly using 3D printing not only for functional prototypes, but also for direct-to-line production parts and factory tooling.

Working with Midlands 3D we can offer

- MJF-produced end-use components with repeatable quality and accuracy

- Custom fixtures, jigs and assembly aids

- Scheduled part production delivered straight to your line

- On-demand service to reduce stockholding and tooling costs

Key Benefits

- Rapid Iteration – Perfect for R&D and validation phases

- Tool-Free Production – Lower costs and lead times, no injection moulds or machining required, eliminating the need to order in volume

- Complex Geometries – Design and print what traditional methods can’t produce

- Customisation – complete flexibility to unique and differentiated parts in every production run

- Lightweighting – Parts engineered for strength and weight optimisation

- Local Supply Chain – UK-based production, with fast and dependable delivery schedules

- Volume Flexibility – Whether you need one part or scheduled batch production we scale with you

Trusted by Motorsport – In Partnership with WSR Racing

Our ongoing partnership with WSR Racing (West Surrey Racing), demonstrates just how additive manufacturing is already delivering performance on the track.

From wind tunnel models and aerodynamic components to pit equipment and race-day replacements, 3D printing allows the team to iterate quickly, reduce weight, and produce parts that have enabled them to be crowned the most successful BTCC team in history.

Beyond the Build – Finishing and Value-Added Services

We understand that in the automotive world, finish and function often both matter equally. Midlands 3D offers a comprehensive suite of print finishing options to meet both aesthetic and technical requirements:

- Vapour Smoothing – Ideal for sealed, scratch resistant, washable surfaces and for improved air and fluid flow rates

Dyeing & Painting – Professional finishes for visual parts or colour coding

PolyShot surfacing – For durability and surface enhancement

Threaded insert fitment & Assembly – Functional parts, ready to use

In addition, we offer value-added services to support your entire product lifecycle:

- 3D scanning and reverse engineering for legacy or damaged parts

- Engineering design support for DfAM

- Inventory management for repeat orders

- PPAP inspection

- Custom packaging and part labelling for line integration

Let’s Get Moving

If you’re ready to make your automotive project lighter, smarter, and faster — Midlands 3D is ready to help.

FREE sample parts available for qualified enquiries.

Talk to Us. Visit Us.

Talk to us and find out what makes working with Midlands 3D so different. If you’ll be in the area, why not arrange to stop by for a guided tour of our manufacturing facility, meet the team and browse our showroom for inspiration.